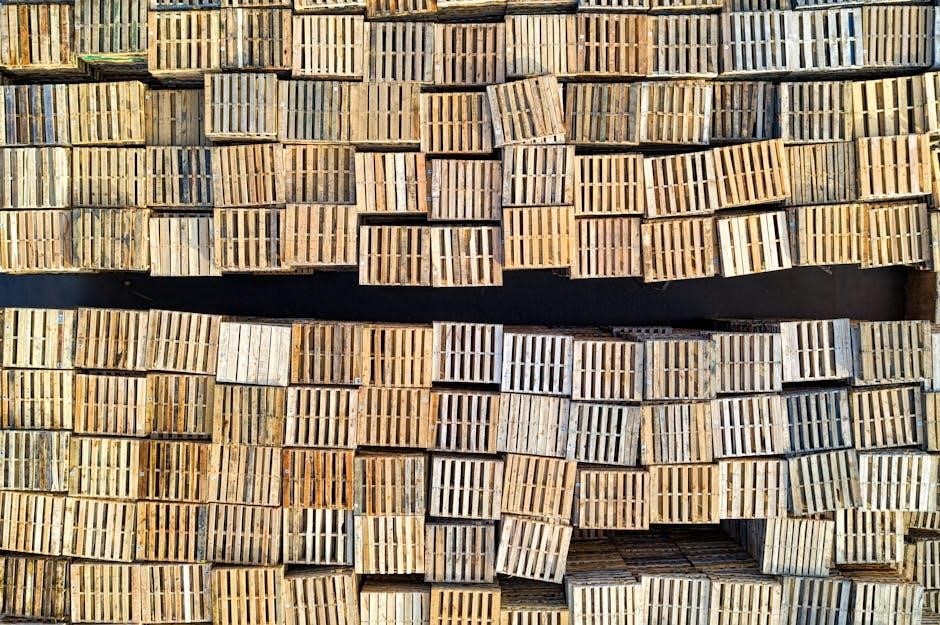

pallet rack identification guide

Pallet rack identification is crucial for recognizing, selecting, and maintaining efficient storage systems․ This guide helps warehouse managers understand types, sizes, and capacities to optimize operations effectively․

1․1 Understanding the Importance of Pallet Rack Identification

Proper pallet rack identification ensures safety, efficiency, and cost savings․ It helps in selecting the right systems, maintaining structural integrity, and optimizing warehouse space․ Accurate identification prevents overload risks and guarantees compliance with safety standards, making it essential for smooth operations and informed decision-making in material handling environments․

1․2 Brief Overview of Pallet Rack Systems

Pallet rack systems are essential for efficient material handling and storage․ They consist of vertical and horizontal structures that support palletized goods, maximizing warehouse space; These systems vary in design, from selective to double-deep racking, offering solutions tailored to specific needs․ Understanding their basics is key to optimizing storage capacity and operational efficiency in any facility․

Common Types of Pallet Racking Systems

Pallet racking systems include selective, double-deep, push-back, pallet flow, and cantilever designs․ Each type offers unique storage solutions, enhancing warehouse efficiency and space utilization effectively․

2․1 Selective Pallet Racking

Selective pallet racking is the most common system, offering direct access to each pallet․ It features upright frames and beams, allowing forklifts to retrieve pallets efficiently․ Ideal for warehouses needing frequent stock rotation, it maximizes space while maintaining accessibility, making it a versatile choice for various storage needs and industries․

2․2 Double-Deep Pallet Racking

Double-deep pallet racking stores pallets two deep in each bay, maximizing storage density․ It requires specialized forklifts like reach trucks to access rear pallets․ Ideal for high-volume warehouses with limited space, this system reduces aisle space while increasing capacity, though it limits accessibility compared to selective racking․

2․3 Push-Back Pallet Racking

Push-back pallet racking uses gravity-fed carts to store pallets up to 6 deep․ Forklifts place pallets on carts, which roll forward as others are removed․ This system supports Last-In, First-Out (LIFO) inventory management, optimizing bulk storage efficiency and reducing aisle space, though it requires specialized handling equipment for access․

2․4 Pallet Flow Racking

Pallet flow racking uses gravity-fed rollers or wheels to move pallets forward as others are removed․ This First-In, First-Out (FIFO) system optimizes inventory turnover and reduces handling time, with pallets flowing smoothly to the picking face․ It’s ideal for high-volume operations, offering dense storage and efficient stock rotation, making it a preferred choice for streamlined warehouse management․

2․5 Cantilever Pallet Racking

Cantilever pallet racking features horizontal arms extending from upright columns, ideal for storing long or irregularly shaped items․ Its adjustable design allows for customized storage solutions, maximizing space efficiency․ Common in industries like automotive or construction, it accommodates bulky loads while maintaining accessibility, making it a versatile option for unique warehouse needs․

Key Components of Pallet Racks

Key components include upright frames, horizontal beams, wire decking, and pallet supports, each essential for structural integrity and efficient storage solutions in warehouses․

3․1 Upright Frames

Upright frames are the vertical structures in pallet racks, providing the main support for the system․ Constructed from steel, they hold the horizontal beams and ensure stability․ Their height and capacity vary, catering to different warehouse needs․ Proper installation is essential for safety and durability, making them a critical component in pallet rack functionality and storage efficiency․

3․2 Horizontal Beams

Horizontal beams are the horizontal supports connecting upright frames, holding pallets and goods․ Made from steel, they vary in length and capacity to suit warehouse needs․ Securely attached to uprights via clips or bolts, they ensure structural stability and support, enabling efficient storage solutions while maintaining the integrity of the pallet rack system․

3․3 Wire Decking

Wire decking is a safety feature added to pallet racks, providing a sturdy surface for pallets․ Made from durable wire mesh, it prevents items from falling through beams, enhancing safety and load distribution․ Easy to install and maintain, wire decking is a practical solution to protect goods and ensure secure storage in warehouse environments․

3․4 Pallet Supports

Pallet supports are additional components installed between beams to enhance stability․ They prevent pallets from sagging and ensure even load distribution, improving safety․ These supports are crucial for heavy or uneven loads, offering extra reinforcement and protecting both the pallets and the racking system from potential damage or collapse during storage operations․

How to Determine Pallet Rack Size and Capacity

Measure pallet dimensions and calculate load weights to determine rack size and capacity․ Ensure beams and uprights match load limits for safe and efficient warehouse storage․

4․1 Measuring Pallet Rack Dimensions

Measure upright frames, horizontal beams, and spacing between levels․ Use a tape measure to record height, depth, and width․ Ensure accuracy to match pallet sizes and warehouse layout needs, optimizing storage efficiency and safety standards effectively․

4․2 Calculating Weight Capacity

Calculate weight capacity by considering pallet weight, rack material thickness, and beam type․ Use manufacturer guidelines and safety margins to ensure structural integrity․ Measure beam deflection and verify load limits to prevent overloading, ensuring safe and efficient storage solutions for your warehouse needs․

Identifying Pallet Rack Manufacturers

Identifying pallet rack manufacturers is crucial for ensuring quality and compatibility․ Recognizing specific features, branding, and design elements helps determine the manufacturer․ Companies like Rack Express and SJF Material Handling offer distinct systems tailored to various needs․

5․1 Recognizing Manufacturer-Specific Features

Manufacturer-specific features, such as beam designs, upright frames, and wire decking, vary across brands․ Companies like Rack Express and SJF Material Handling offer unique systems․ Identifying these features helps determine the manufacturer and ensures compatibility with existing systems․ Always examine branding, serial numbers, and design elements for accurate identification․

Safety Considerations for Pallet Rack Identification

Inspecting for damage or wear and understanding load limits are critical․ Ensure structural integrity to prevent accidents and maintain warehouse safety, adhering to manufacturer guidelines․

6․1Inspecting for Damage or Wear

6․1 Inspecting for Damage or Wear

Regularly inspect pallet racks for dents, rust, or bent frames․ Check connections and fasteners for tightness․ Replace damaged components promptly to ensure stability and prevent collapses․ Use visual checks and maintenance schedules to identify issues early, ensuring a safe working environment and compliance with safety standards․

6․2 Understanding Load Limits

Understanding load limits is essential for safe pallet rack operations․ Each system has a maximum weight capacity, specified by the manufacturer․ Exceeding these limits can lead to structural failure․ Always verify weights and distribute loads evenly to prevent overloading․ Consult manufacturer guidelines to ensure compliance and safety in your warehouse environment․

Maintenance Tips for Pallet Racks

Regular inspections and prompt repairs are vital for pallet rack longevity․ Check for damage, tighten loose bolts, and ensure all components are stable to prevent accidents․

7․1 Regular Inspection Practices

Conduct regular inspections to identify damage or wear on pallet racks․ Check for bent frames, loose bolts, and damaged decking․ Ensure all components are secure and within weight limits․ Train staff to report issues promptly to maintain safety and prevent collapse risks․ Schedule inspections monthly or after significant rack adjustments․

7․2 Repairing Damaged Components

Address damaged pallet rack components promptly to ensure safety and functionality․ Replace bent or corroded uprights and beams with manufacturer-approved parts․ Tighten loose bolts and anchors․ For minor damage, such as dented decking, consider repairs or replacements based on severity․ Always consult professionals for major structural repairs to maintain system integrity and prevent collapses․

Case Studies: Real-World Applications

Explore how pallet rack systems are applied across industries, from manufacturing to retail, optimizing storage and efficiency in diverse operational settings and scales․

8․1 Pallet Rack Systems in Different Industries

Pallet rack systems are essential across various industries, from manufacturing to retail, each requiring tailored solutions․ Manufacturing facilities often use heavy-duty systems for bulky items, while automotive warehouses employ cantilever racks for long materials․ Retail distribution centers opt for selective racking for fast access, ensuring efficient inventory management and space optimization to meet industry-specific demands effectively․

Factors Affecting Pallet Rack Selection

Warehouse layout, inventory size, weight limits, and industry-specific requirements are key factors in selecting pallet racks․ Understanding these elements ensures optimal storage solutions and operational efficiency․

9․1 Warehouse Space and Layout

Warehouse space and layout significantly influence pallet rack selection․ Assessing available floor space, ceiling height, and aisle widths ensures efficient installation․ Maximizing vertical storage and maintaining accessibility are critical for optimizing the facility’s capacity and workflow․ Proper planning prevents overcrowding and enhances operational efficiency, ensuring safe and organized material handling processes․ Effective use of space is essential․

9․2 Inventory and Load Requirements

Understanding inventory and load requirements is vital for selecting appropriate pallet racking․ Assessing pallet sizes, weights, and types ensures compatibility with the system․ Calculating load capacities and considering special handling needs, such as fragile or oversized items, helps determine the most suitable racking configuration․ This ensures safe and efficient storage, preventing overloading and potential damage to goods or infrastructure․

Proper pallet rack identification ensures efficient, safe, and cost-effective warehouse operations․ By understanding types, sizes, and capacities, businesses can make informed decisions for optimal storage solutions and management․

10․1 Summary of Key Identification Points

Identifying pallet racks involves understanding their types, sizes, capacities, and components․ Recognizing manufacturers and ensuring safety through inspections and maintenance are crucial․ Proper identification optimizes storage efficiency, safety, and operational productivity in warehouses․

10․2 Final Tips for Effective Pallet Rack Management

Regularly inspect racks for damage, ensure weight limits are respected, and follow manufacturer guidelines․ Optimize warehouse layout for efficiency, and train staff on proper pallet handling․ Maintain accurate inventory records and consider future storage needs when selecting or upgrading systems․