honeywell 8000 installation manual pdf

Welcome to the Honeywell 8000 Installation Manual, your comprehensive guide for installing and configuring the VisionPro 8000 thermostat; This manual covers installation steps, advanced settings, safety precautions, and troubleshooting tips to ensure a smooth setup and optimal performance. Designed for both professionals and homeowners, it provides detailed instructions to unlock installer options, configure schedules, and enable Wi-Fi connectivity. Follow this guide to ensure your thermostat is installed correctly and functions efficiently.

System Requirements and Compatibility

The Honeywell 8000 thermostat is compatible with 1H/1C and 2H/1C HVAC systems, including heat pumps with auxiliary heat. Ensure electrical requirements are met, and safety precautions are followed during installation.

Overview of Compatible HVAC Systems

The Honeywell 8000 thermostat is compatible with a variety of HVAC systems, including 1H/1C and 2H/1C heat pumps, with or without auxiliary heat. It also supports conventional heating and cooling systems. The thermostat works seamlessly with dual-fuel systems, ensuring efficient operation. For heat pumps, it accommodates auxiliary/emergency heat relay configurations. The system is designed to integrate with standard HVAC equipment, making it a versatile solution for different home setups. Proper compatibility ensures reliable performance and energy efficiency, tailored to meet diverse heating and cooling needs.

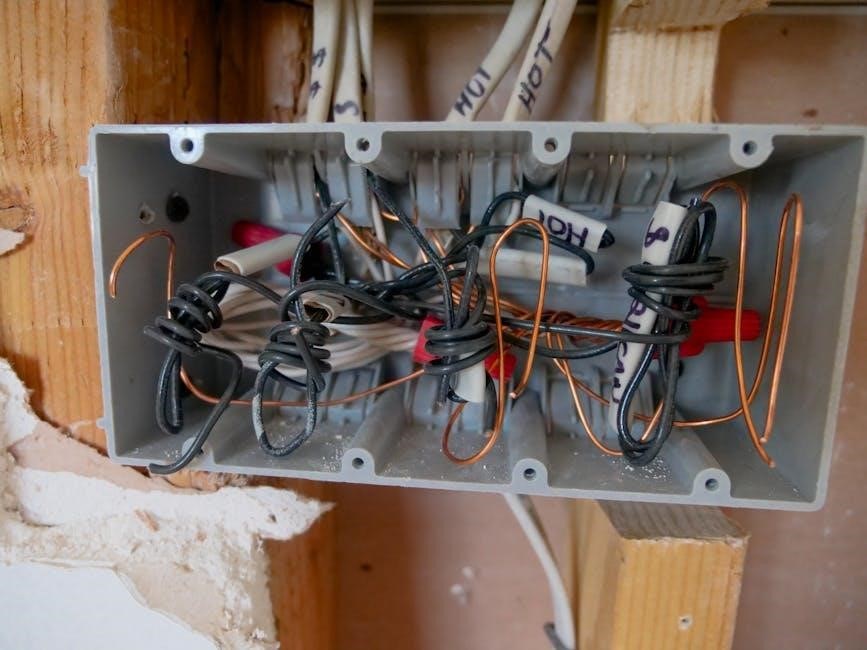

Electrical Requirements and Safety Precautions

Before installing the Honeywell 8000 thermostat, ensure the system meets electrical requirements. Disconnect power to avoid electrical shock or damage. The thermostat requires a 24VAC common wire (C) and is compatible with most standard HVAC systems. Use appropriate wire gauges and connections to prevent overheating. Always follow local electrical codes and safety guidelines. Installation should only be performed by a trained technician. Proper grounding and wiring are essential to ensure safe and reliable operation. Failure to adhere to these precautions may result in system malfunctions or safety hazards.

Installation Steps

Begin by separating the wallplate from the thermostat. Drill holes for wall anchors, install them, and mount the wallplate. Connect the wires to the appropriate terminals, ensuring secure connections for reliable operation.

Preparing the Site and Tools Needed

Before starting, disconnect power to the HVAC system to avoid electrical hazards. Gather necessary tools, including a drill, 3/16-inch and 7/32-inch drill bits, wall anchors, and a screwdriver. Ensure the installation area is clean, flat, and free from obstructions. For drywall, drill 3/16-inch holes, and for plaster, use 7/32-inch holes. Insert wall anchors to secure the wallplate. Verify all wiring is labeled and organized. Ensure the thermostat and wallplate are separated before mounting. Follow safety guidelines to prevent damage or injury during the installation process.

Mounting the Thermostat and Wallplate

Begin by separating the thermostat from the wallplate. Remove any protective covering from the thermostat and wallplate. Locate the installation area, ensuring it is level and accessible. Mark the wall for drilling, using the wallplate as a template. Drill pilot holes for wall anchors, then insert the anchors securely. Mount the wallplate by screwing it into the anchors, ensuring it is level and firmly attached. Once the wallplate is installed, align the thermostat with the wallplate and gently press until it clicks into place. Ensure all connections are secure and the thermostat is properly seated.

Wiring the System and Connecting Terminals

Disconnect power from the HVAC system before starting. Use the wiring diagram provided to identify terminals (R, C, Y, G, etc.). Connect wires to the wallplate terminals, ensuring secure and correct connections. Match the wires from the HVAC system to the corresponding terminals on the thermostat. Tighten all connections firmly to avoid loose wires. Double-check the wiring diagram for accuracy and verify that all terminals are properly connected. Once wired, restore power and test the system to ensure proper operation. Proper wiring is critical for safe and efficient thermostat function.

Unlocking Installer Options

Access advanced settings by entering the Installer Setup Menu using the date code as the password. This allows configuration of system parameters for optimal performance.

Accessing the Installer Setup Menu

To access the Installer Setup Menu on the Honeywell VisionPro 8000 thermostat, start by touching the Menu option on the home screen. From there, scroll and select Dealer Information. At the bottom of this screen, you’ll find the Date Code, which serves as the password for unlocking installer options. Return to the main menu, select Installer Options, and enter the Date Code when prompted. This grants access to advanced configuration settings, enabling you to customize system parameters for optimal performance. Ensure you follow these steps carefully to avoid errors during setup.

Using the Date Code as a Password

The Date Code, located in the Dealer Information section, acts as the default password for accessing advanced installer settings. Once you’ve navigated to the Installer Options menu, enter the Date Code when prompted. This step is crucial for unlocking configuration options, allowing you to customize system parameters such as schedules, IAQ settings, and Wi-Fi connectivity. Ensure the Date Code is entered accurately to avoid access issues. This security feature protects settings from unintended changes, maintaining system integrity and performance.

Configuring Advanced Settings

Customize system parameters to optimize performance, including scheduling, IAQ options, and Wi-Fi connectivity. Ensure precise configuration to avoid errors and maintain efficient HVAC operation.

Setting Up Schedules and IAQ Options

Configure custom schedules and IAQ (Indoor Air Quality) options to enhance comfort and efficiency. Access the Installer Setup Menu using the Date Code as the password. Define temperature settings for different times of the day, ensuring optimal comfort. Adjust IAQ parameters to improve air circulation and filtration. Use the touchscreen interface to customize these settings, balancing energy savings with indoor air quality. Regularly review and update schedules to align with lifestyle changes or seasonal needs for maximum performance and energy efficiency.

- Set daily schedules for heating and cooling.

- Activate IAQ modes for improved air quality.

- Customize settings to match your preferences.

Enabling Wi-Fi and Remote Access

To enable Wi-Fi and remote access on your Honeywell 8000 thermostat, navigate to the Installer Setup Menu. Use the Date Code as the password for access. Once logged in, select the Wi-Fi option and connect to your home network by entering the password. After successful connection, download the Honeywell Home app to control your thermostat remotely. This feature allows you to adjust settings, monitor energy usage, and receive notifications from anywhere, enhancing convenience and energy management. Ensure stable internet connectivity for seamless remote operation.

- Connect to your home Wi-Fi network.

- Download and install the Honeywell Home app.

- Control your thermostat remotely via the app.

Troubleshooting Common Issues

Identify common issues like wiring problems or display errors. Check connections, ensure proper power supply, and restart the system if necessary. Refer to the manual for detailed solutions to resolve operational issues effectively.

Resolving Wiring and Connection Problems

To address wiring issues, first disconnect power to avoid electrical hazards. Check all connections for tightness and accuracy, ensuring terminals match the system requirements. Use a multimeter to verify wiring integrity and detect short circuits or open wires. Consult the wiring diagram in the manual to confirm proper connections. If issues persist, verify the equipment monitor and auxiliary heat settings. Reset the system after correcting wiring errors. If problems remain, refer to the troubleshooting section or contact a certified technician for assistance.

- Ensure all wires are securely connected to the correct terminals.

- Verify the wiring diagram matches your HVAC system configuration.

- Use a multimeter to test for continuity or shorts in the wiring.

- Check for loose connections or damaged wires that may cause malfunctions.

Addressing Display and Communication Errors

If the display is blank or unresponsive, ensure the thermostat has power and batteries are installed correctly. Reset the device by removing batteries or disconnecting power for 30 seconds. For communication errors, verify Wi-Fi connectivity and check the router’s signal strength. Ensure the thermostat is properly registered to your Honeywell Home account. If issues persist, perform a factory reset by holding the menu button for 10 seconds. Consult the manual for detailed troubleshooting steps or contact Honeywell support for further assistance.

- Check power sources and battery connections.

- Restart the thermostat to resolve temporary glitches.

- Verify network settings and Wi-Fi signal strength.

- Perform a factory reset if communication issues remain unresolved.

Maintenance and Updating the Thermostat

Regular maintenance ensures optimal performance of your Honeywell 8000 thermostat. Clean the display with a soft cloth to prevent dust interference. Replace batteries every 5 years or as indicated. For hardwired systems, ensure power is stable. Check for firmware updates via the menu or Honeywell Home app. Update promptly to access new features and security enhancements. Refer to the manual for detailed instructions on updating software and performing routine checks to maintain efficiency and functionality.

Regular Maintenance Tips

Regular maintenance ensures your Honeywell 8000 thermostat operates efficiently. Clean the display with a soft, dry cloth to remove dust and fingerprints. For battery-powered models, replace batteries every 5 years or when the low-battery indicator appears. In hardwired systems, ensure a stable power supply to prevent malfunctions. Check for firmware updates via the menu or Honeywell Home app and install them promptly to access new features and improvements. Refer to the manual for detailed instructions on updating software and performing routine checks to maintain optimal performance and reliability.

Updating Firmware and Software

To keep your Honeywell 8000 thermostat functioning at its best, regular firmware and software updates are essential. Check for updates via the Honeywell Home app or directly through the thermostat menu. Select “Update Firmware” and follow the on-screen instructions to download and install the latest version. The system may restart during the update process, which is normal. Ensure uninterrupted power during the update to avoid any issues. Updated firmware often includes new features, performance improvements, and bug fixes to enhance your thermostat’s functionality and compatibility.

Congratulations on completing the installation of your Honeywell 8000 thermostat! This manual has provided a comprehensive guide to ensure your system operates efficiently and safely. By following the steps, you’ve successfully configured settings, unlocked installer options, and prepared for future updates. Regular maintenance and timely firmware updates will keep your system running smoothly. Refer to this manual for troubleshooting or adjustments. Enjoy the enhanced comfort, energy savings, and advanced features your Honeywell 8000 thermostat offers. Happy heating and cooling!