fundamentals of modern manufacturing 7th edition pdf

The 7th Edition of Fundamentals of Modern Manufacturing provides a comprehensive overview of manufacturing principles, blending traditional methods with cutting-edge technologies like automation and additive manufacturing.

Overview of the 7th Edition

The 7th Edition of Fundamentals of Modern Manufacturing offers an updated exploration of manufacturing practices, emphasizing the integration of traditional techniques with modern innovations. It covers emerging technologies like automation, additive manufacturing, and sustainable practices, providing a holistic view of the industry. The edition includes revised chapters, case studies, and practical examples to enhance understanding. This resource is essential for students and professionals seeking insights into contemporary manufacturing methodologies.

Key Features and Updates in the 7th Edition

The 7th Edition introduces enhanced coverage of Industry 4.0, smart manufacturing, and sustainable practices. It includes new chapters on additive manufacturing, automation, and data analytics. Updated case studies and practical examples provide real-world insights. The edition also features revised diagrams and improved readability. Key updates emphasize emerging technologies like AI and IoT, ensuring alignment with current industry trends. This edition is a valuable resource for understanding modern manufacturing advancements.

Core Principles of Modern Manufacturing

Modern manufacturing emphasizes standardization, continuous improvement, and technology integration. It focuses on optimizing processes, reducing waste, and ensuring sustainability while maintaining high product quality and customer satisfaction.

The Evolution of Manufacturing Processes

Manufacturing processes have evolved significantly, transitioning from traditional craftsmanship to mechanized production and now to advanced digital methodologies. The integration of automation, robotics, and additive manufacturing has revolutionized production efficiency and product quality. These advancements enable manufacturers to produce complex components with precision while minimizing waste. Industry 4.0 and smart manufacturing further emphasize data-driven decision-making, ensuring sustainable and adaptable production systems. This evolution underscores the importance of innovation in meeting modern industrial demands and customer expectations.

Lean Manufacturing and Six Sigma

Lean manufacturing focuses on eliminating waste and optimizing resources to enhance efficiency and value for customers. Six Sigma employs data-driven methodologies to reduce defects and variations in processes. Together, these approaches aim to improve product quality and operational excellence. By integrating lean principles with Six Sigma tools, manufacturers achieve sustainable performance improvements, fostering a culture of continuous improvement and customer satisfaction.

Manufacturing Processes and Technologies

Manufacturing processes and technologies encompass a range of methods and innovations, from traditional machining to advanced automation and additive manufacturing, ensuring efficiency and innovation in production.

Advanced Material Processing Techniques

Advanced material processing techniques involve cutting-edge methods to shape and transform materials with precision. These include laser cutting, 3D printing, and CNC machining, ensuring high accuracy and efficiency. Modern technologies enable the production of complex geometries and customized products, reducing waste and improving sustainability. Such techniques are integral to industries requiring high-performance materials, from aerospace to healthcare, driving innovation and productivity in manufacturing systems. These methods are continuously evolving to meet global demands for superior quality and durability.

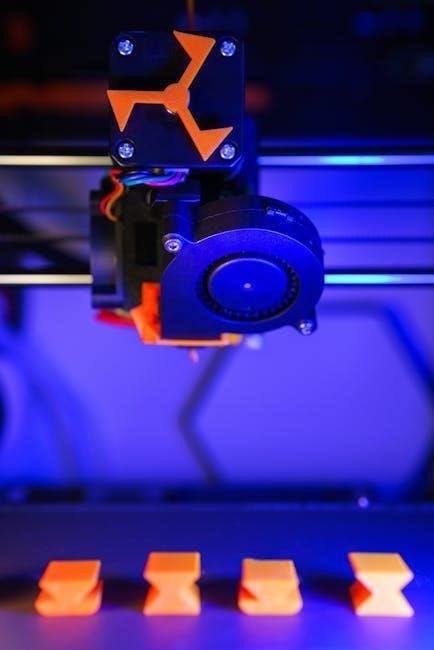

Additive Manufacturing and 3D Printing

Additive manufacturing, including 3D printing, revolutionizes production by creating products layer-by-layer. This method enables complex geometries, reduces material waste, and allows rapid prototyping. Technologies like binder jetting and direct energy deposition are highlighted, offering versatility for various industries. Applications range from aerospace to healthcare, showcasing its adaptability. Additive manufacturing enhances design freedom, supports sustainability by minimizing waste, and streamlines production processes, making it a cornerstone of modern manufacturing innovation and efficiency.

Quality Control and Assurance

Quality control ensures products meet standards through monitoring and testing, while quality assurance focuses on preventing defects by improving processes, enhancing reliability, and maintaining customer satisfaction.

Total Quality Management (TQM)

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction by integrating quality into all organizational processes. It fosters a culture of excellence, employee involvement, and data-driven decision-making. TQM’s core principles include customer focus, process-centered approaches, and ongoing training. By implementing tools like Statistical Process Control (SPC) and Plan-Do-Check-Act (PDCA), organizations achieve higher productivity, reduced defects, and enhanced stakeholder confidence, ensuring long-term success and sustainability.

Statistical Process Control (SPC)

Statistical Process Control (SPC) is a methodology for monitoring and controlling processes to ensure consistent quality. It uses statistical tools like control charts to detect deviations from desired performance. By analyzing data trends, SPC helps identify anomalies, enabling corrective actions to prevent defects. This approach minimizes variability, enhances process stability, and improves overall product quality, making it a cornerstone of modern manufacturing and quality assurance systems.

Sustainability in Modern Manufacturing

Sustainability in modern manufacturing focuses on reducing environmental impact through green practices, energy efficiency, and resource optimization. It aligns with global standards, enhances competitiveness, and integrates advanced technologies for eco-friendly production.

Green Manufacturing and Environmental Impact

Green manufacturing emphasizes sustainable practices to minimize environmental impact. It involves using eco-friendly materials, reducing waste, and implementing energy-efficient processes. By adopting renewable energy sources and optimizing resource consumption, manufacturers can significantly lower carbon emissions and comply with environmental regulations. This approach not only supports global sustainability goals but also enhances corporate responsibility and competitiveness in modern industries.

Energy Efficiency in Manufacturing Systems

Energy efficiency in manufacturing systems is crucial for reducing operational costs and environmental impact. Modern techniques include optimizing power consumption, using smart technologies, and implementing sustainable practices. By integrating renewable energy sources and improving process design, manufacturers can achieve significant energy savings while maintaining productivity. This approach aligns with global sustainability goals and enhances the overall efficiency of manufacturing operations.

Automation and Robotics in Manufacturing

Automation and robotics are revolutionizing manufacturing by enhancing efficiency, precision, and productivity. These technologies enable streamlined processes, reduce human error, and optimize resource utilization, driving modern manufacturing forward.

Industrial Robotics and Machine Learning

Industrial robotics combined with machine learning enables intelligent automation, where robots adapt to tasks through real-time data analysis and continuous learning. This integration optimizes manufacturing processes, enhances precision, and reduces downtime. Advanced algorithms allow robots to perform complex tasks, such as assembly and quality control, with higher accuracy. Machine learning also improves predictive maintenance, ensuring operational efficiency. These technologies are transforming industries like automotive and electronics, driving innovation and efficiency in modern manufacturing. Robotics and AI are essential for future-proofing production systems.

Smart Factories and the Internet of Things (IoT)

Smart factories leverage the Internet of Things (IoT) to create interconnected systems, enabling real-time data exchange between devices, sensors, and software. IoT optimizes manufacturing processes, enhances monitoring, and improves decision-making. By integrating IoT, factories achieve greater efficiency, reduced downtime, and better resource utilization. Advanced analytics and machine learning further enhance operational insights. This connectivity drives innovation, sustainability, and adaptability, positioning smart factories as the cornerstone of Industry 4.0 and modern manufacturing advancements.

Design for Manufacturability

Design for Manufacturability focuses on creating products that are easier, less expensive, and more reliable to produce. It emphasizes simplicity, modularity, and compatibility with production processes to minimize costs and enhance quality.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

CAD and CAM are integral to modern manufacturing, enabling precise design and production. CAD software creates detailed digital models, while CAM translates these designs into machine instructions, optimizing fabrication processes. Together, they enhance accuracy, reduce errors, and streamline production, making them essential tools for achieving efficiency and quality in manufacturing systems. These technologies are widely adopted across industries to meet the demands of complex and customizable product development;

Design for Assembly and Disassembly

Design for Assembly (DFA) focuses on simplifying product assembly, reducing production costs, and enhancing efficiency by minimizing part count and complexity. Design for Disassembly (DFD) emphasizes ease of dismantling for recycling, maintenance, and eco-friendly practices. Both strategies minimize environmental impact while improving manufacturability. These approaches are crucial for sustainable manufacturing, ensuring products are cost-effective, environmentally responsible, and aligned with modern production standards.

Supply Chain Management

The 7th Edition explores strategies for optimizing supply chain management, focusing on efficiency, technology integration, and global process alignment to enhance production and distribution networks effectively.

Global Supply Chain Optimization

Global supply chain optimization focuses on streamlining processes to enhance efficiency, reduce costs, and improve collaboration across international networks. The 7th Edition highlights strategies for integrating advanced technologies, such as data analytics and IoT, to monitor and predict demand, ensuring seamless production and distribution. By leveraging standardized formats and digital tools, manufacturers can achieve transparency, traceability, and sustainability in their supply chains, aligning with global standards and fostering resilience in an ever-evolving market landscape.

Just-In-Time (JIT) and Agile Manufacturing

Just-In-Time (JIT) manufacturing emphasizes producing goods just in time to meet demand, minimizing inventory and waste. Agile manufacturing extends this by enabling rapid adaptation to market changes. The 7th Edition explores how JIT and agile systems improve efficiency, reduce lead times, and enhance product quality. By integrating flexible production processes and responsive supply chains, manufacturers can achieve higher customer satisfaction while maintaining cost-effectiveness in dynamic global markets.

Industry 4.0 and Digital Transformation

Industry 4.0 integrates cyber-physical systems, IoT, and AI into manufacturing, enabling smart factories and digital twins for enhanced efficiency and innovation, driving global competitiveness.

Cyber-Physical Systems and Digital Twins

Cyber-physical systems integrate physical and computational elements, enabling real-time communication and automation in manufacturing. Digital twins, as virtual models of physical systems, allow for simulation, monitoring, and optimization of processes. Together, they enhance decision-making, improve efficiency, and reduce errors, fostering innovation and agility in modern manufacturing environments.

Big Data and Analytics in Manufacturing

Big data and analytics play a pivotal role in modern manufacturing by enabling the analysis of vast datasets to optimize processes. Advanced tools and techniques, such as machine learning and predictive analytics, help manufacturers identify trends, improve quality, and reduce operational costs. By leveraging real-time insights, companies can enhance decision-making, streamline production, and achieve greater efficiency in supply chain management and product development.

Case Studies and Real-World Applications

Case studies provide real-world examples of modern manufacturing in action, showcasing success stories and practical insights. These applications highlight how innovative technologies enhance efficiency and foster innovation in industries.

Success Stories in Modern Manufacturing

Success stories highlight real-world applications of modern manufacturing techniques, showcasing industries like aerospace and automotive. Companies leveraging automation, IoT, and additive manufacturing report significant efficiency gains, reduced waste, and cost savings. These examples demonstrate how integrating advanced technologies with methodologies like Lean and Six Sigma drives innovation and sustainability, setting benchmarks for future manufacturing practices and inspiring others to adopt similar strategies for competitive advantage.

Challenges and Lessons Learned

Challenges in modern manufacturing include high implementation costs, workforce training needs, and data security risks. Lessons learned emphasize the importance of gradual technology integration, cross-department collaboration, and robust cybersecurity measures. Manufacturers must balance innovation with practicality, ensuring that new technologies align with long-term business goals. These insights help industries navigate complexities and achieve sustainable growth in an evolving manufacturing landscape.

Future Trends in Manufacturing

Future trends include advancements in AI, IoT, and sustainable practices, driving smarter, greener, and more connected manufacturing systems. These innovations promise increased efficiency and reduced environmental impact.

Emerging Technologies and Innovations

Emerging technologies such as AI-driven predictive maintenance, advanced robotics, and digital twins are revolutionizing manufacturing. These innovations enable real-time process optimization, enhanced precision, and sustainable production. Additive manufacturing and smart factories are also gaining traction, integrating IoT and big data for seamless operations. Such advancements are reshaping the industry, driving efficiency, and reducing environmental impact while fostering competitiveness in a rapidly evolving global market.

The Role of AI and Autonomous Systems

AI and autonomous systems are transforming manufacturing by enabling predictive analytics, real-time decision-making, and autonomous operations. Machine learning optimizes production workflows, while robotic systems enhance precision and efficiency. These technologies reduce human intervention, improve safety, and drive sustainability. Autonomous systems also enable adaptive production lines, ensuring flexibility and scalability in response to market demands, making them indispensable in modern manufacturing environments.

The 7th Edition offers a comprehensive understanding of modern manufacturing, blending theory with practical insights. For further study, explore additional resources like APA guides, PDF references, and industry publications.

The 7th Edition covers essential manufacturing principles, from traditional methods to advanced technologies like Industry 4.0 and digital twins. It emphasizes sustainability, automation, and data-driven decision-making, while providing practical insights into lean manufacturing, quality control, and supply chain optimization. Case studies and real-world applications highlight emerging trends, ensuring a well-rounded understanding of modern manufacturing practices and their future directions.

Additional Resources for Further Study

For deeper exploration, readers can access academic journals, industry reports, and online platforms like ResearchGate and ScienceDirect. The APA Publication Manual and ASTM standards provide detailed guidelines. Websites like MDPI and Springer offer comprehensive resources on manufacturing innovations. Additionally, eBooks from reputable publishers and conference proceedings are valuable for specialized topics, ensuring access to the latest research and practical applications in the field of modern manufacturing.